en

|

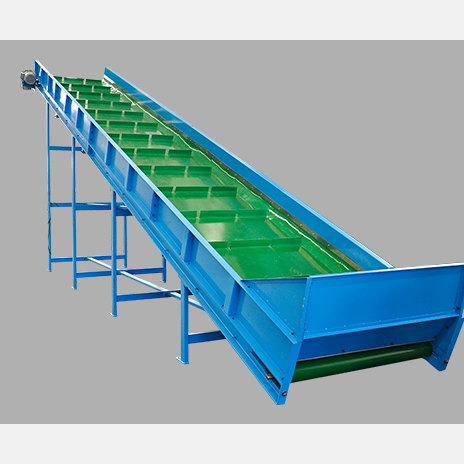

Chain plate conveyor

The horizontal baler machine can realize auto

< Click to view this product > feeding, improving working efficiency, and saving labor costs. |

Shredding (Crushing) Machine

This series is widely used for processing a wide range of materials, including plastic, metal, wood, paper, waste, and others. The shredded materials are easy to compress and package for recycling purposes.

< Click to view this product > |

Full-Automatic Baler

The horizontal fully automatic wire bundling machine is widely used in packaging plants, carton factories, printing plants, garbage sorting stations, and professional recycling stations. It is suitable for bundling waste paper, cardboard, plastics, fabrics, fibers, household garbage, etc. This machine can be used with assembly lines, air pipe feeding, and other methods.

|

Chain plate conveyor

A horizontal baler machine can realize auto feeding, improve working efficiency, and save labor costs.

|

English

English