en

|

Plate Separator

Designed for air and waste materials

< Click to view this product > separation. |

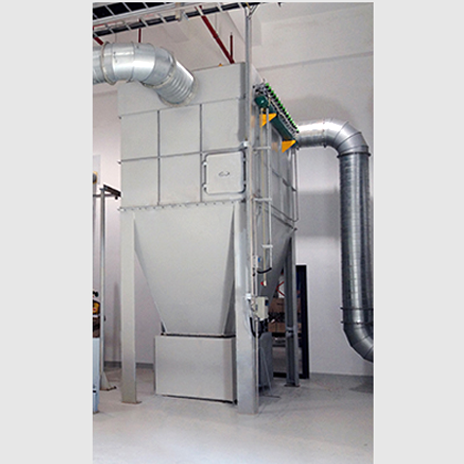

Bag-type Dust Collector

The bag-type filter is widely used in industries including printing, corrugated cardboard, plastics, chemicals, electricity, mining, building materials, and metallurgy.

< Click to view this product > |

Full-Automatic Baler

The horizontal fully automatic model automatic wire bundling machine is widely used in packaging plants, carton factories, printing plants, garbage sorting stations, and professional recycling stations. It is suitable for bundling waste paper, cardboard, plastics, fabrics, fibers, household garbage, etc. This machine can be used with assembly lines, air pipe feeding, and other methods.

|

English

English