In the sanitary care products industry, scraps (non-woven fabric, dust-free paper) and defective products (e.g., diapers, sanitary napkins, pads) can be automatically collected, shredded, packaged, and dedusted via an online recycling system.

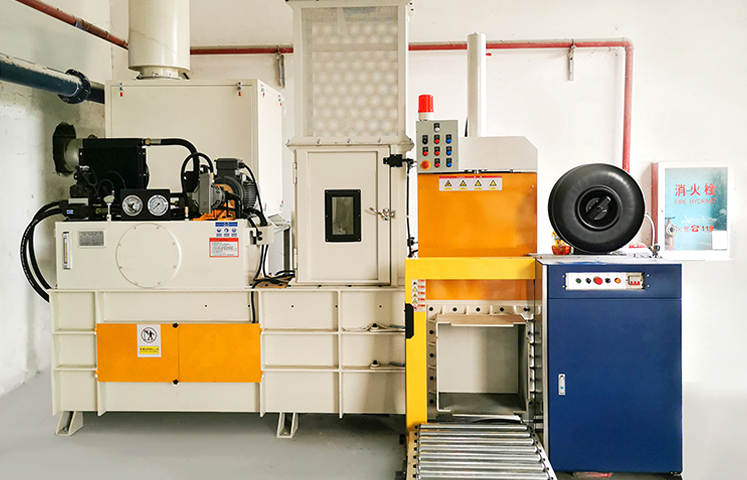

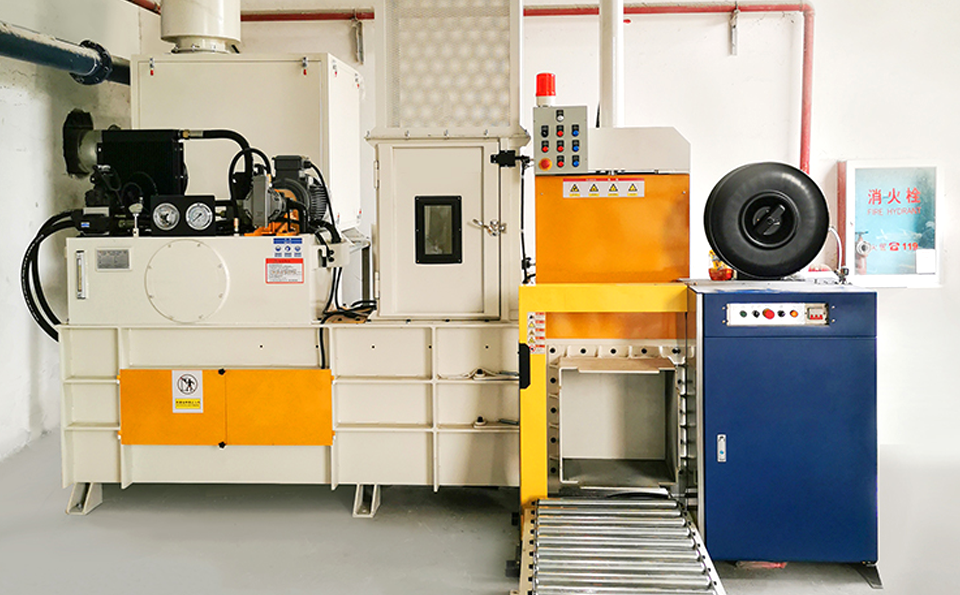

Leftover materials are conveyed to the baling room by an air conveying system (configured with fan ducts). After static electricity is eliminated, the materials are fed into a baling machine for automatic baling—enabling unmanned operation. Dust generated in the air conveying system is captured by a bag filter, then pressed into blocks via a briquetting machine to prevent secondary dust pollution.

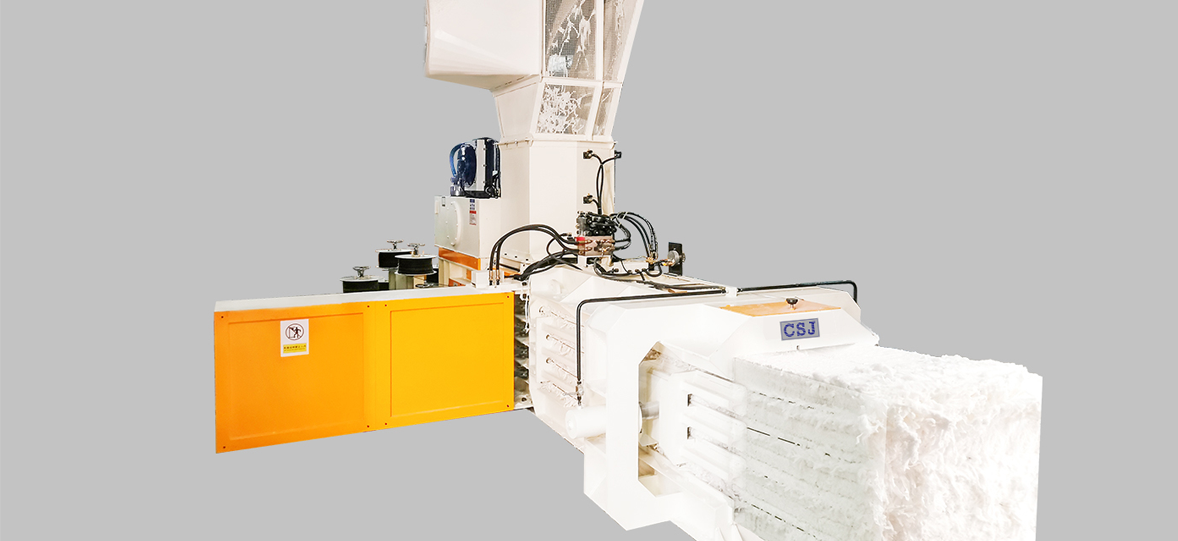

Defective products can be transported to the crushing and baling machine either by air delivery or manual intervention (via a conveyor line). First, the products are finely shredded (to prevent polymer leakage from defective items), then automatically baled for convenient recycling.

Since this waste is flammable and its dust is explosive, the conveying fan, baler, and dedusting system can be customised with explosion-proof features to ensure safe production. Additionally, the entire system significantly reduces labour costs, improves workshop environmental conditions, and boosts production efficiency.

English

English