Plastic Sorting Process:

Recycled mixed plastic materials are transported by vehicle to the unloading area for temporary storage. A loader then feeds the materials into a stepper flying shear bag-breaking machine, which splits large bags into bulk materials (this improves the screening efficiency of subsequent sorting equipment).

After bag-breaking, the materials are conveyed to a three-dimensional screen, which classifies them into 3D materials, 2D materials, and undersize fractions based on their climbing force (ability to overcome gravity) and three-dimensional behavior. The main components in the 3D fraction are PET and HDPE; these are identified and positioned by an intelligent AI robot vision detection system (tailored for different material components).

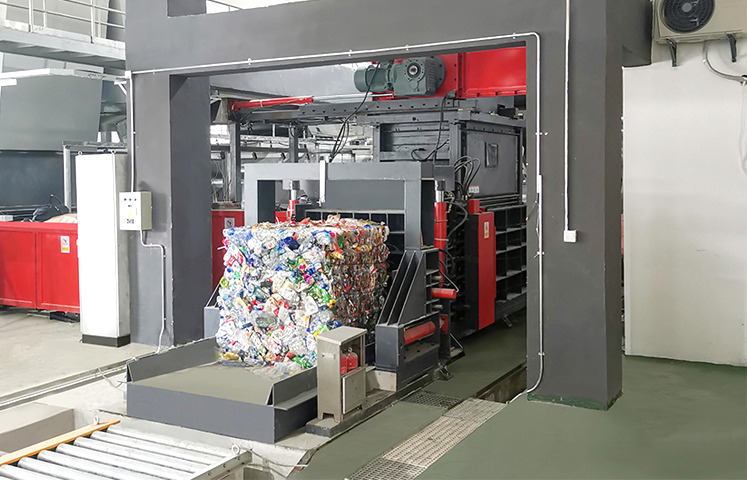

Transparent PET, variegated PET, white HDPE, and variegated HDPE are sorted and stored separately, then packaged individually. The remaining materials (including 2D objects from the 3D sieve and undersize fractions) are collected, stored, and packaged together.

Paper Sorting Process:

Recycled paper is transported by vehicle to the unloading area for temporary storage. After manual trimming and unpacking, the paper is fed into a plate chain conveyor, which evenly transports the material to an OCC (Old Corrugated Container) screen (screen aperture: 300mm). The screen separates the material into oversize (>300mm) and undersize (≤300mm) fractions.

The main component of the >300mm oversize fraction is yellow cardboard. After manual sorting to remove additional impurities, this cardboard is transported to a temporary storage area for storage and packaging.

The main component of the ≤300mm undersize fraction is miscellaneous paper. An intelligent AI robot vision detection system identifies, locates, and sorts out any yellow board paper in this fraction; the remaining miscellaneous paper is then transported to a temporary storage area for storage and packaging.

English

English